Aerial lifts are vehicle-mounted devices such as bucket trucks, cherry pickers or other lifts with extendable platforms used to elevate personnel to access elevated areas. These are supported by a boom that can either be a telescopic lift, which is a straight arm or an articulating boom lift, which is able to bend, making it useful for jobs that require extra movement to avoid hazards or provide better accessibility. It is important, however, to keep safety top-of-mind when operating these equipment.

Aerial lifts are vehicle-mounted devices such as bucket trucks, cherry pickers or other lifts with extendable platforms used to elevate personnel to access elevated areas. These are supported by a boom that can either be a telescopic lift, which is a straight arm or an articulating boom lift, which is able to bend, making it useful for jobs that require extra movement to avoid hazards or provide better accessibility. It is important, however, to keep safety top-of-mind when operating these equipment.

Aerial lift safety is the utmost importance since many workers are injured or killed on aerial lifts each year. The following are the known hazards associated with aerial lifts which can lead to personal injury or death:

- Fall from elevated level

- Objects falling from lifts

- Tip-overs

- Ejections from the lift platform

- Structural failures (collapses)

- Electric shock (electrocutions)

- Entanglement hazards

- Contact with objects

- Contact with ceilings and other overhead objects

A great way to start incorporating safety into our workday is to go through an aerial lift safety checklist. Creating a safety process will get us in the habit of checking for any red flags before and during lift operation. This safety process must include the training and certification of authorized operator, pre-start inspection, work zone inspections and safety procedures during the actual operation.

Training and Certification of Authorized Operator

Only those who are trained, certified and authorized are allowed to operate an aerial lift. Confirm that operator’s certifications are up-to-date and that they are familiar with the manufacturer guidelines for each lift they will operate. Operator’s training should include the following:

- Explanations of electrical, fall, and falling object hazards

- Procedures for dealing with hazards

- Recognizing and avoiding unsafe conditions in the work setting

- Instructions for correct operation of the lift (including maximum intended load and load capacity)

- Demonstrations of the skills and knowledge needed to operate an aerial lift before operating it on the job

- When and how to perform inspections

- Manufacturer’s requirements

Employers are required to retrain workers who they observe operating an aerial lift improperly and/or an accident occurs during aerial lift use. It must also be kept in mind that there are different types of aerial lifts that may require operators to undergo trainings applicable to its type.

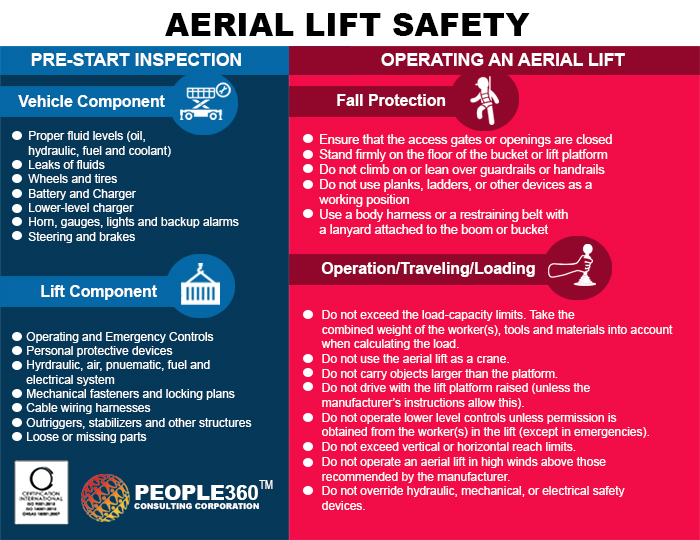

Pre-start Inspection

Take some time to inspect every single part of the lift prior to each work shift to verify that the equipment and all its components are in safe operating condition. In conducting the pre-start inspection we must follow the manufacturer’s recommendations and include a check of the following:

Vehicle components

- Proper fluid levels (oil, hydraulic, fuel and coolant)

- Leaks of fluids

- Wheels and tires

- Battery and charger

- Lower-level controls

- Horn, gauges, lights and backup alarms

- Steering and brakes

Lift components

- Operating and emergency controls

- Personal protective devices

- Hydraulic, air, pneumatic, fuel and electrical systems

- Fiberglass and other insulating components

- Missing or unreadable placards, warnings, or operational, instructional and control markings

- Mechanical fasteners and locking pins

- Cable and wiring harnesses

- Outriggers, stabilizers and other structures

- Loose or missing parts

- Guardrail systems

Do not operate any aerial lift if any of these components are defective until it is repaired by a qualified person. Remove defective aerial lifts from service (tag out) until repairs are made.

Work Zone Inspection

A safe work zone is just as important as safe machinery. When working indoors, we should examine the ceiling to make sure it’s an adequate height and if there are any potential overhead hazards. We should also examine the floor and surrounding area for unstable surfaces, bumps or anything else that can cause an obstruction.

When working outside, inspect the surrounding area for any drop-offs, holes, ditches, slopes, debris and other floor obstructions that need to be cleaned up or avoided. We should also take note of nearby overhead electrical lines and communication cables. High winds and severe weather conditions are major hazards to watch out for that can tip over or otherwise endanger our employees.

Safety during Operation of Aerial Lifts

It is necessary to take safety precautions not just prior to each work shift but also during the actual operation of aerial lifts. We must follow the safe operating procedures for fall protection, operation, traveling, loading, overhead protection and stability in the work zone.

Fall Protection

- Ensure that access gates or openings are closed

- Stand firmly on the floor of the bucket or lift platform

- Do not climb on or lean over guardrails or handrails

- Do not use planks, ladders, or other devices as a working position

- Use a body harness or a restraining belt with a lanyard attached to the boom or bucket

- Do not belt-off to adjacent structures or poles while in the bucket

Operation / Traveling / Loading

- Do not exceed the load-capacity limits. Take the combined weight of the worker(s), tools and materials into account when calculating the load.

- Do not use the aerial lift as a crane.

- Do not carry objects larger than the platform.

- Do not drive with the lift platform raised (unless the manufacturer’s instructions allow this).

- Do not operate lower level controls unless permission is obtained from the worker(s) in the lift (except in emergencies).

- Do not exceed vertical or horizontal reach limits.

- Do not operate an aerial lift in high winds above those recommended by the manufacturer.

- Do not override hydraulic, mechanical, or electrical safety devices.

Overhead Protection

A good rule of thumb is to always treat lines, wires and other conductors as energized regardless if they are down or appear insulated. If we can’t completely avoid power lines, we should keep at least 10 feet away preventing possible accidents. We should also steer clear of positioning aerial lifts between power lines and other overhead hazards when possible. Insulated aerial lifts offer protection from electric shock and electrocution by isolating you from electrical ground. However, an insulated aerial lift does not protect you if there is another path to ground (for instance, if you touch another wire). To maintain the effectiveness of the insulating device, do not drill holes in the bucket.

Stability in the Work Zone

Outriggers and brakes add a layer of stability to prevent any unexpected shifts in the ground or the lift. These should be used even if the ground seems stable at first glance. Wheel chocks are essential for ensuring our lift stays in place when working on inclines. Adding scaffolding to the platform or bucket can greatly increase the risk of falling. We should avoid this regardless if the scaffolding falls under the capacity limits.

Keeping these safety tips in handy may help us in the safe use and operation of different aerial lifts. Proper training, adequate pre-inspections and heightened awareness at all times are key ways to keep us and our team safe.

Sources: